|

Contributed by Jerry Fossey How do I specify Metal Composite Material (MCM) manufacturers vs. fabricators?

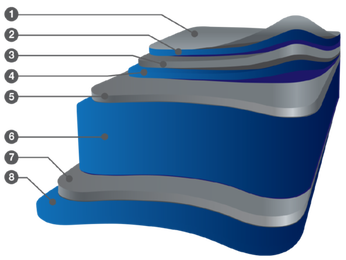

This is probably one of the most confused topics in the ACM/MCM industry, so I hope that this short post will help clarify the difference between the Manufacturer and Fabricator of Metal Composite Material (also known as Aluminum Composite Material or ACM). MCM consists of two skins of metal sandwiching a core material, which provides greater rigidity and superior flatness than sheet metal or plate. The MCM Manufacturer is the one that makes sheets of MCM, in a process where the skins and core are fused together in a continuous coil process. There are also some manufacturers that press skins to a core one sheet at a time, however this is generally known to be a lower quality bond, which is important when you consider the harsh conditions an exterior building envelope is required to withstand. The MCM Fabricator cuts, routs, folds and otherwise processes the MCM to fabricate panels to mount on the building. These fabricators can either have their own tested installation system using aluminum extrusions, or they can use a third party’s installation system. So which one should I specify? The MCM Manufacturer or the Fabricator? The answer is BOTH! There are many testing requirements, some of which apply to the Manufacturer and some to the Fabricator. Anything related to the MCM itself, such as fire rating and surface finish belong to the Manufacturer. Tests that require panel fabrication generally apply to the Fabricator, such as wind loads and water penetration. It is important then to clearly differentiate between the Manufacturer and the Fabricator in your specifications. I hope this helps build a greater understanding in the Composite Metal Wall Panel industry!

2 Comments

2/16/2018 04:16:12 am

Thanks for clarifying the doubts regarding both the techniques, but I would prefer fabrication process as I think it is ideal for aluminum extrusions and has outshined the traditional MCM manufacturing.

Reply

In Metal Fabrication, there are two basic classifications of work: Material and fabricated. A metal fabrication or fabricating work usually consists of cutting or forming materials from steel, titanium, iron, brass, aluminium alloys or other alloys in shapes and sizes into shapes and designs for use as accessories, swings, signet, plates, screws, pistons, nails, axles and hinges, etc., Modern technology has afforded the capacity to fabricate intricate designs and shapes from metal and plastics at unprecedented speed and quality, which has given rise to a new era of metallurgical engineering known as Metal Fabrication Technology. Metal fabricators use various techniques like roll forming, sheet metal forming, conversion of solid forms, abrasive metal plating, electroplating, laser curing, etc.

Reply

Leave a Reply. |

AboutLet's Fix Construction is an avenue to offer creative solutions, separate myths from facts and erase misconceptions about the architecture, engineering and construction (AEC) industry. Check out Cherise's latest podcast

Get blog post notifications hereArchives

March 2022

Categories

All

|

RSS Feed

RSS Feed