|

Contributed by Liz O'Sullivan What’s a hiker to think? You can see the summit from here, the hiking trail guidebook says the trailhead is up here somewhere, but the street signs don’t match the road names on the maps or in the guidebook, and now you see these conflicting signs on what you’re pretty sure is the right road. The green sign at the beginning of the road says “Private Property Beyond This Point, No Trespassing,” which usually means that one should not proceed. End of story, right?

Well, there’s another sign, farther away, up this same road. That brown sign says “Respect Private Land, Stay on Main Road,” which implies that it’s actually ok to proceed up this “No Trespassing” road, but only if you don’t veer off the road. Then, of course, there’s that little tacked-on “No Parking” sign, which implies that it’s ok to drive up this road, but only if you don’t park on it. I’m a rule follower, so these conflicting signs confound and paralyze me. Surely we’d never create anything as confusing as this in the construction industry, would we? I did a whole bunch of invoicing last month, because I had a ridiculous amount of work in April. I took a good, hard, look at my time on one of those projects, and confirmed my suspicions that I’d gone waayyy over my budgeted hours on this lump-sum-fee project. Wow, what a deal my client got, right? All those extra hours spent making the specs perfect? Well, not exactly. Every few days while I was working on the project, I was sent a digital pile of information by my architect-client, who received stuff from the owner team. Many of these documents conflicted with each other, sometimes giving as many as 3 different conflicting instructions for one thing. I spent a lot of time trying to reconcile all the different directives – time that I actually needed for other things, like product research for the project, coordination for the project, work on other projects, family time, and sleep. As most of the info was related almost solely to the specifications, and it came from the owner team, who should have known what they wanted since this wasn’t their first one of these buildings, the architect didn’t spend too much time reviewing it before forwarding it on. So my questions about this info were confusing to them, and, for some reason, some were unanswerable by the owner. I’ve never been on the contractor team for a project, but I think I know how estimators feel when the architectural drawings say one thing, the structural drawings say something different, and the specs say a third different thing. An estimator may want to just take the risk of pricing what makes the most sense, and hoping it’s right. Asking questions during the bid period is sometimes an inefficient use of time, and experience may show that some answers aren’t worth the time spent. Perhaps this is why the design team sees surprises when submittals come in. Back to that hike. As it turns out, if you can get to a place where you can receive a strong enough cellular signal, and you can look at a satellite view of the area with the conflicting signage, you can figure out whether or not you were on the right road to the trailhead. Or maybe you skip that research, you just take that risk of trespassing, and you drive up that road. It’s a rutted 4-wheel-drive road, so you are hoping it’s the right road because it’s going to be a rough ride. Turns out the trailhead and parking area are a half mile up that road! Apparently, you just have to ignore that first sign. What a terribly inefficient standard operating procedure for communications of any type. Issuing conflicting instructions to a group requires multiple parties to either all risk making the wrong guess (and risk losing time or money), or all spend time doing the same research to figure out which of the conflicting instructions is the intended one. Whether the group you’re trying to communicate with is hikers, bidders, or your design team, isn’t it best to just issue clear, concise, correct, and complete information the first time? Or maybe we could just shoot for non-conflicting.

12 Comments

Contributed by Sheldon Wolfe, FCSI The purpose of construction documents is simple: They tell the contractor what is needed to complete a project. How best to do that has been a subject of debate for a long time, even though a basic set of rules has been used at least as far back as the 1940s. In his "The Case For the Streamlined Specification", published in the July 1949 Construction Specifier, Ben John Small referred to a book titled "Specifications" that was written in 1896; the older book apparently discussed some degree of streamlining. That's fine as far as it goes, but if the intent is to clearly communicate with the contractor, are we doing as well as we could? Architects and specifiers have a nice collection of rules for organizing information, but do they make sense for the contractor? Our rules are fairly consistent, and they are generally accepted by design firms, but can they be improved? A large project many take a year or more to complete, yet we still have inconsistencies and conflicts. Is it fair to expect a bidder, who typically has only a few weeks to figure out what we want, collect subcontract bids (many of which are incomplete or include qualifications), decide how much to include to cover the inevitable problems, and arrive at a competitive price? Can we do better than asking contractors to find the critical information in a haystack of information that is less important? Let's start with what works. Streamlining is the practice of removing many of the words we would use in ordinary conversation, but which add nothing to construction documents. A big step toward simplification is achieved by a simple change of mindset; if you understand that specifications and drawings are instructions written to the contractor, rather than a disinterested explanation of what is to happen, the rest will be easier. When teaching certification classes, I tell the class to write as if they are talking directly to the contractor. If you are talking with a contractor you won't say, "The contractor shall fill the bollard with concrete." Instead, you would say, "Fill the bollard with concrete." As noted, this is a big first step, one that will automatically eliminate the "shall be" phrases that still are far too common. But even more can be done to reduce the length of specifications without losing critical information. While some things may need something approaching a complete sentence, most requirements can be reduced to what amounts to a checklist. Each item begins with a subject, followed by a colon (defined to mean "shall be" or similar term), followed by the relevant property. For example: Air content: 5 to 8 percent. Insulation: ASTM C578, Type IV. Note that this checklist approach translates very well to properties found in BIM objects. It's fairly common practice to eliminate the articles a, an, and the. In most cases, this works well, but I retain the article when referring to the Architect, the Contract, the Contractor, and the Work, to take care of those situations when those terms occur at the beginning of a sentence. Otherwise, there is no way to differentiate between the contractor identified in the agreement (Contractor) and a contractor working on the same building but under a different contract. Even though streamlining is relatively easy to do, many firms - and even commercial guide specifications - do not use it as much as they can. Another common problem is lack of coordination: specifications that conflict with each other and with drawings, drawing notes that appear to have been written without any understanding of what's in the specifications, and drawing notes that ignore the basics of writing specifications. If that's the best we can do, and it appears that it is, we haven't made much progress in the last hundred years. Click Read More ------> Contributed by Elias Saltz Continuing education for architects is a necessary component of the profession. It is the main vehicle by which we are able to keep up to date with developments in material science, construction methods, business procedures, document creation, et cetera. All licensed architects are required to attend a certain number of Continuing Education Units (CEUs) to maintain their licenses and the AIA requires continuing education of its members to maintain membership.

All programs put on by my CSI chapter of Chicago offer CEUs and the chapter pays AIA every year to maintain its status as an education provider, and we offer far more units than architects are required to obtain. Typically, though, most architects will obtain a majority of their CEU hours by attending “lunch and learn” sessions arranged by an education coordinator at their firm, and at my company I fill that role. My firm is not a registered CEU provider, so our lunch and learn programs are provided by product reps whose programs have been registered and approved by AIA through its Continuing Education System (CES) to provide learning units. AIA-approved courses are also accepted by other organizations as well, such as GBCI and CSI, which require continuing education to maintain their advanced certifications. Over time, I’ve become more conscious of trying to be skeptical of claims being made as part of CES lunch and learn courses, and also evaluating whether I feel like I’ve gotten any value (other than lunch) for my time and attention. Most CES programs have some nuggets of useful information, and I don’t feel any qualms about accepting the credit for attending. On rare occasions a CES program is complete baloney; I refuse the credit (and maybe even leave the room - taking my lunch with me as compensation for my wasted time) and one time I even began wondering how the AIA decides what qualifies for an approved CES course in the first place. I started by reviewing the AIA CES Provider Manual Policies and Resources booklet and the Provider Manual Resources Toolkit. The bulk of the information in these documents is procedural and administrative: how to write high quality learning objectives, how to get your course approved and listed by AIA, how to register attendees, what introductory slides are required, and when you can and cannot discuss proprietary information. There is very little guidance about what the course content may or may not cover. Out of 34 pages in the “Policies and Resources” document, only one page - page 15 - talks about Health, Safety, Welfare (HSW) content (though to be fair, the “Resources Toolkit” talks more about HSW). Another few sentences provide the following minimal guidelines for content:

The existence of useless courses is a potential black eye for the AIA as the administrator of the CES system, and something they should really care about, in my opinion. However, there’s no evidence that the AIA intends to do anything about this in the near term. To compensate for this deficit, my firm has begun requiring that all CEU presenters agree to a set of rules that go above and beyond those required by the AIA as a condition for our agreeing to let them present. If rules like these were widely adopted, this could go toward fixing continuing education.

Architects should be able to rely on the continuing education they receive to actually improve their knowledge and abilities. Until we improve how we validate what we’re being taught, the CES and CEU programs it offers should be considered to be of questionable value. Contributed by Joseph Lstiburek of Building Science Corporation The perfect wall is an environmental separator—it has to keep the outside out and the inside in. In order to do this the wall assembly has to control rain, air, vapor and heat. In the old days we had one material to do this: rocks. We would pile a bunch or rocks up and have the rocks do it all. But over time rocks lost their appeal. They were heavy and fell down a lot. Heavy means expensive and falling down is annoying. So construction evolved. Today walls need four principal control layers—especially if we don’t build out of rocks. They are presented in order of importance:

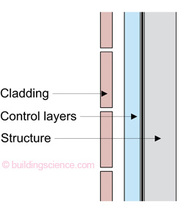

The best place for the control layers is to locate them on the outside of the structure in order to protect the structure (See Figure 1). When we built out of rocks the rocks didn’t need much protection. When we build out of steel and wood we need to protect the steel and wood. And since most of the bad stuff comes from outside the best place to control the bad stuff is on the outside of the structure before it gets to the structure. Also, after generations of building out of rocks folks somehow got the idea that they wanted to be comfortable—and they figured out that rocks were not the best insulation. I mean rocks are not that bad compared to windows—memo to architects: you can’t build an energy efficient green building out of glass, but you can get design awards and we all know which is more important. Back to rocks, they are heavy and you need a lot of them to make the wall have any decent thermal resistance so we invented thermal insulation. But where to put the insulation? If we put the insulation on the inside of the structure the insulation does not protect the structure from heat and cold. Remember we really do want to protect that darn structure—especially for the sake of making the structural engineers life more happy. Expansion, contraction, corrosion, decay, ultra violet radiation, and almost all bad things all are functions of temperature. So all the control layers go on the outside. Keep the structure from going through temperature extremes and protect it from water in its various forms and ultra violet radiation and life is good. Figure 1 (Above): “The Perfect Wall”—In concept the perfect wall has the rainwater control layer, the air control layer, the vapor control layer and the thermal control layer on the exterior of the structure. The claddings function is principally to act a an ultra-violet screen. Oh, and architects might consider the aesthetics of the cladding to be important.

What about this air control thing? Well air can carry a lot of water and water is bad for the structure. So we have to keep air out of the structure as well because of the air-water thing—or if we let it get into the structure we have to make sure it does not get cold enough to drop its water. Now, just one other thing, tends to be important if you intend on living in the building or working in the building or keeping things safe in the building, we might want to control the interior environment. We especially ought to be concerned about what is in the interior air because when we are in the interior we tend to breathe it. Well, it turns out that we can’t control air until we enclose air. So we need an honest to god airtight enclosure in order to provide conditioning such as filtration and air change and temperature and humidity control. And once again the best place to control this air thing is on the outside of the structure—but under the insulation layer so the air does not change temperature. Presto: the perfect wall. A water control layer, air control layer and vapor control layer directly on the structure and a thermal control layer over the top of the other control layers (see Figure 1 again). This was figured out long before I was born—I think the Canadians figured it out first [1], but the Norwegians have some claims to this plus the Russians. I am going to go with the Canadians on this one because I am biased and proud of it. Also, I met Professor Hutcheon, and that is a story for the grandkids when I get some—memo to Christy and Andrew: so what’s the delay here? For a more detailed discussion of the physics of all of this go to the old masters: Hutcheon and Handegord [2] and the new kids on the block Burnett and Straube [3]. In a beautiful bit of elegance and symmetry if you lie the perfect wall down you get the perfect roof (Figure 2) and then when you flip it the other way you get the perfect slab (Figure 3). The physics of walls, roofs and slabs are pretty much the same—no surprise (Figure 4). This insight was shone into a whole generation of practitioners by Max Baker [4] when I was first getting started. Click Read More ------> Contributed by Marvin Kemp On several recent projects in our office, we've had some atypical mockups: discrete pieces of laboratory casework, full room mockups and performance-tested mockups. Even on projects with the more typical aesthetic mockups, there seems to be differing opinions of the purpose, process and approach to making mockups useful and successful. Like with all items in construction, the requirements for mockups start in one or two places. The project manual should include the requirements for mockups in Division 01 and in certain technical sections while drawings may also be provided to indicate the extent of the larger mockups required. Our firm's project manuals include requirements for mockups in Section 01 40 00 Quality Requirements. Our typical Section 01 40 00 defines mockups this way: "Mockups: Full size physical assemblies that are constructed on-site. Mockups are constructed to verify selections made under sample submittals; to demonstrate aesthetic effects and, where indicated, qualities of materials and execution; to review coordination, testing, or operation; to show interface between dissimilar materials; and to demonstrate compliance with specified installation tolerances. Mockups are not Samples. Unless otherwise indicated, approved mockups establish the standard by which the Work will be judged." I particularly like the sentence "Mockups are not Samples." Our Section 01 40 00 does not contain a definition of "samples" but I think that definition is generally understood: small pieces of the actual material, thickness, color and finish that will be used in the work. While the mockup definition includes the notion of creating an assembly, it is not an assembly of samples, as noted in the sentence referenced above. A measure of each material, in the exact size, thickness, color and finish specified must be used to create the mockup, but not a series of easily and readily available samples. The other ideas put forth in the mockup definition that are important are the purposes of the mockup. Note the plural term "purposes." A mockup can used to set the quality, demonstrate the aesthetics and review coordination, testing and operation of the materials. These are all important and legitimate uses for the mockup. I think the commonly misunderstood idea is "to review coordination, testing, or operation." We currently have in construction the fourth residence hall renovation for a long time client. The four buildings are similar and have similar systems installed. For the four buildings, we have had three different construction managers and a myriad of different trade contractors. We have some clear wall framing details that incorporate the window details, fan coil unit and its piping, wall insulation and other items. These details have evolved based on knowledge gained in the early buildings. For the first two renovations, we directed an off-site mockup be built to help all trades understand the coordination needed as the client was seeking to minimize space lost within the room: even 1/2-inches are important. The off-site mockup was also critical because the first three renovations featured summers only construction so the residence halls could be occupied during the school year. Coordination was critically important as the contractors had 11 weeks to mobilize, demolish, install new, punch out, final clean and demobilize. For this fourth renovation, the CM and trade contractors have 12 months. Unfortunately, the CM did not seem interested in the mockup at all. I was unable to convince him of the necessity or utility of it. It is a contract requirement, so he did it, but he did not seem interested in learning from it. I find that to be incredibly short sighted, but as I said, we do have very clear wall framing details. However, at a critical time in the construction schedule, he was directed to remove a significant portion of non-conforming work and replace it. If this had occurred in just the mockup room, it would not be a big deal. However, the trade contractor had installed this non-conforming work across 1-1/2 floors of a five floor building. This story is played out on project after project and I partially blame us as the architect. Here's how this particular mockup is described in Section 01 40 00: "Bedroom Mock Up: In one resident bedroom, install fan coil, exterior wall framing, high impact gypsum board, fan coil enclosure, fan coil control, insulation and vapor barrier." While this is an apt description of the work result, we should have mentioned the purpose of the mockup and how the client would like to see the work in progress as well as the work result. While out of sequence work is problematic to the CM, is that less costly to he and the trade contractor than removing 1-1/2 floors of installed work? Click Read More ------> |

AboutLet's Fix Construction is an avenue to offer creative solutions, separate myths from facts and erase misconceptions about the architecture, engineering and construction (AEC) industry. Check out Cherise's latest podcast

Get blog post notifications hereArchives

March 2022

Categories

All

|

RSS Feed

RSS Feed