|

Contributed by Eric D. Lussier

Hi.

It's Eric. Yeah, it's been a while. I know. I'm sorry. Please accept my apology? Thank you. I could use your help. As many in the AEC (Architecture/Engineering/Construction) industry face a return to some sort of office-life, normalcy or jobsites after COVID-19, I wanted to take this time to use your knowledge, experience and assistance in matters that are near and dear to my professional life, concrete and flooring finishes. Concrete moisture, surface planarity, adhesives, new products, lack of training and the skilled labor shortages are quite possibly just the tip of the iceberg when it comes to what many of us deal with on a daily basis. I would VERY MUCH appreciate it if you could take just three minutes to answer three different questions as it pertains to concrete and flooring. The best part is you can remain completely anonymous if you wish. Don't feel like answering this Google Form? Then please email me at [email protected] or send a video or text to me at 802-922-8407. I cannot thank you enough. I'm excited to read your replies.

39 Comments

Contributed by Eric D. Lussier Today the exhibit hall opens for the 45th edition of the World of Concrete in Las Vegas. If you've never been to WOC, let me try and put it into context for you, as I had the chance to host a Let’s Fix Construction workshop for Prosoco in 2018.

So, with an annual knowledge share of this magnitude, one would expect that the literal world of concrete would be cutting-edge that contains less flaws than in years past, and is an exact science, right? Well, sometimes it’s nice to assume, but you know what they say about that. Anyone who has followed my social media posts or Let's Fix Construction posts from over the years knows that as a flooring contractor, our daily fights with concrete are aplenty. And they don't seem to be getting any better. From the constant battles with concrete moisture to the surface planarity to unpredictable curling after placement, the fight goes on into the 12th round and I'd hate to say that concrete might just be winning by TKO. But don't get me wrong, the future with concrete is looking up. Polishing technologies have flooring finishes on its heels and the longevity of concrete as a building material will never be second guessed. Floor preparation equipment is becoming more productive and more affordable. And its use as a building product is certainly not going anywhere anytime soon. But it starts at the placement and that is where the industry may need the most help. Proper specifications need to be in place to set a better slab, but more importantly, the concrete contractor needs to read them and recognize that there are always better ways to build a mousetrap. When Cherise Lakeside spoke at World of Concrete in 2016 to 50 concrete contractors, she asked a few pointed questions (and blogged about it). Their answers offer insight into their world of concrete:

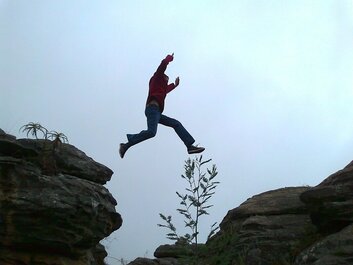

The future of the World of Concrete show (book it! January 18-22, 2021) will always be bright as the mousetraps look beautiful and there are plenty to see, touch and feel. But the industry will continue to be challenged with the same 11th hour issues if the specifications aren't challenged, changed, and enforced and especially if the contractors refuse to admit that there are always better ways to do things. Contributed by Eric D. Lussier I've been saying it for years now. The public's perception of just what is a construction worker has to change. Sure, the hardhat and overalls wearing carpenter, working outdoors and swinging a hammer does indeed exist. But construction is SO MUCH MORE. Construction is the process, art, or manner of constructing something. Using that definition, if you work within the construction industry you could hold one of well over a hundred different job roles or titles. Due to our heavy involvement in the Construction Specifications Institute and CSI's diversified membership base of ALL players within the built environment, when Let's Fix Construction was founded we chose to view the construction industry as this more encompassing whole. We chose AEC - Architecture, Engineering & Construction - as our definition, a term that is more widely recognized and accepted today.

So whether that is more of a skilled tradesman position, such as a flooring installer, cement mason, painter, welder, ironworker or boilermaker, or perhaps it may be on the design end, such as an architect or engineer (or one of dozens of roles within an office), construction is so far beyond our hammer-swinging carpenter that has become the unfortunate public face. During this Careers in Construction Month, it’s important that we not only talk to, but inform the younger generation on not just what construction is, but what construction can be. Today, Monday October 7th, is Careers in Construction Day. Meant to be a day of action on social media for those working within construction, please take a moment to share a picture of yourself on the job and post it to social media with the tag #CICDAY2019 in order to give people a true glimpse into our daily lives. While you're at it, feel free to use our hashtag #FixConstruction Contributed by Eric D. Lussier Once upon a time, I wrote about a project we were awarded in an article titled ‘Not Quite Ready Yet’. That piece was a follow up to piece called 'Project Compaction: Not Just for Soil'. In that article, I had taken part in a pre-construction meeting on February 25th where the contractor asked if we could install flooring on a slab five days after the concrete pour. Needing to understand that one correctly, I said run that by me one more time? Their contract to us had flooring finishes being installed between March 21st and April 12th and as of that call, the concrete slab had not even been placed. Well, time flies and I’m here to provide an update on the project. Officially, we’re done as of Friday July 26th. Which all-in-all, isn’t horrible as that’s only three months and change behind the schedule that was dictated to us.

Numerous times in the last week I was struck by a recurring issue, and one that wraps up my trilogy on this particular project in one of the five boroughs of New York City. If you ask 100 people what they would like more of in the day, I would guess that a vast majority would answer time. Ask the modern marketer what one of their primary objectives is and most will tell you its to gain peoples time and attention. All the time we’re being reminded how our time is short and how time is of the essence and within construction, it always seems to be a race against time and before we know it, crunch time. Well, I beg to ask, in a business where time is money, and money is time, how did we get to a point where we seemingly no longer respect someone else’s time? So, on this project that we just wrapped, we were informed that there were site inspections scheduled for Monday on Friday the 19th. Now in a borough of 1.5 million people, I’m going to go out on a limb and guess that our customer, the General Contractor, had to schedule this inspection at least a few weeks in advance, if not a month or more. So, how is it we were told that we wouldn’t be able to work Monday, (which then turned into Tuesday as well) on a Friday afternoon? Contributed by Roy Schauffele Late fall and during all winter, concerns and problems arise with air barrier applications on CMU (Concrete Masonry Unit). I know because I get the phone calls. Generally speaking, the fluid applied water-based vapor permeable air barriers go on OK but take a long time to cure or set.

Additionally, I’ve observed a myriad of job site problems with self-adhered vapor impermeable sheets, flashings and tapes. The vapor impermeable materials were applied properly but exhibited blistering and lack of adhesion within days. When investigated there was always liquid water on the adhered side of these sheets. Observations of quite a few jobs leads me to state that, in this investigation, the vast majority of “problem” jobs had the following in common:

OK, let’s deal with what will lead to an excellent new construction air barrier installation and long-term performance: 1. If the Architect/Specifier has specified a dry water repellent in the CMU, it is already causing a potential problem with the adhesion of a water-based air barrier or primer. This issue has been written about previously in an article in Coatings Pro Magazine July 2018 “Legacy Specifications, Wall and Air Barrier Performance”. The Air Barrier installer absolutely needs to make the Architect/Specifier aware of this prior to bid. 2. If the project is wide open with doors, bay doors and windows not finished or openings not protected from water entry, then a tremendous amount of water can enter the CMU causing some of the problems referenced above. The top of the walls and window openings should be treated in such a way as to prevent water from running in to these open areas. One of my friends and great technical writer in Austin, TX, Mr. Dave Watts, RA, has the following statement in his specifications: Section 04 20 00, 3.18 PROTECTION OF FINISHED WORK, 3.18.e “Protect tops of masonry with waterproof coverings secured in place without damaging masonry. Provide coverings where masonry is exposed to weather when work is not in progress.” |

AboutLet's Fix Construction is an avenue to offer creative solutions, separate myths from facts and erase misconceptions about the architecture, engineering and construction (AEC) industry. Check out Cherise's latest podcast

Get blog post notifications hereArchives

March 2022

Categories

All

|

RSS Feed

RSS Feed