|

Contributed by Eric D. Lussier With 2018 behind us, and with that another great year of articles, podcasts and many workshops across the nation (and even one in Canada), Let’s Fix Construction looks forward to 2019, as do many others. A new year starts with fresh energy, renewed spirit, a hopeful change of habits and a positive outlook.

With 2019 facing us and 2018 in the rearview mirror, Let’s Fix Construction is using this post for a Call to Arms. A challenge, if you will. Hopefully you can identify your role, or more than one, in this list. Don’t see a challenge that calls to you? Identify your own. Step out of your comfort zone and move yourself and the architecture, engineering and construction (AEC) industry forward. To Owners: Educate yourself before you proceed with your project, especially if it is your first one! Take the time to learn the roles of the major players in a building project. Vet your architect, construction manager, general contractor and any other major contractor or consultant that you are going to be contractually obligated to. You don’t have to be best friends, but it will go a long way if you know who you will be working with and get along with them. What makes them tick? What sets them off? What are their expectations? What are their expectations of you? And in the end, if you really want to educate yourself about a project, get a copy of the Construction Specifications Institute’s ‘Project Delivery Practice Guide’. It could just be the best $129 you’ve ever spent. AND save you a thousand-fold in the long run. To Architects: Projects are getting increasingly complex and the demands on you, your supporting staff and ultimately, your entire office are growing as well. The world we live in changes rapidly and with that the demands that are put on all the major players in a project. You’re being asked to do much more in much less time for the same amount of money. Practice saying no. Don’t be afraid to lose a client that expects more from you without understanding your point of view. Make sure you and your staff are compensated appropriately for your time. Track all costs and analyze your data. If you are able to reference a completed project that is similar in size and scope of a new project you are working on, you will be able to substantiate to the Owner why you have the requests, both financial and otherwise, that you do.

8 Comments

Contributed by Brent Williams

Hi, I’m Brent Williams and I’m a self-described construction materials geek. I come from an architecture background, but I was serendipitously detoured into the product rep world…and I’ve never looked back. Why, you ask?

Because I love working in the visual oriented design world that we live in. I’ve been lucky enough to become a hyper-specialist in one, weird little construction product. But my product is unusual & amazing, it solves a myriad of issues in the industry and I completely love my amazing job. A big chunk of what a professional building product rep does on a daily basis is explain exactly where, why, how and how not to deploy these products to the design community. In medical terms, our friends in the Architecture world are General Practitioners, while the rep is a Micro Neurosurgeon. Architects, by the design of their craft, need to know at least a little bit about everything. Me? I need to know everything that there is about one tiny little thing. More importantly, I need to know what THEY need to know about my tiny little corner of the world. And therein lies the magic, the alchemy, as it were. Product Reps have to communicate quickly and accurately, at an incredibly high level of proficiency, in both directions…both to and from the client. You simply must be empathetic, intuitive and proactive. Not the simplest matrix of executables and doubly tough to execute rapidly and on the fly. Nothing less than excellence will be tolerated by the modern construction industry. An experienced rep needs to be both an incredible listener yet anticipate issues and questions almost before they are spoken. Frankly, all of us in the product representation arena either hold this skill set, or we’re not around very long. Check any employment website, or look on LinkedIn, and there are lots of vacancies for reps and lots of reps looking for employment. If you think about it, just about everyone involved in the design industry must possess most of this skill set in order to be able to sustain the construction process. You either communicate at scale, or you’re gone. No quarter. You can’t do a proper program unless you can communicate at a very high level, with all of the constituents in and on a project. Contributed by Chris Maskell The flooring industry is constantly challenged by the same repeating issues. Installing too early, wet concrete, non-flat sub-floors, sub-floor surface not prepared, heat not on, windows not in and lack of installer training and certification. In fact, as construction speeds up to meet demands for faster build times and with the threat of an increase in the cost of borrowing money lurking in the economic wings, the provision of acceptable conditions for the flooring contractor is becoming less likely.

This raises the importance of supporting those in the construction team (Building Owner, Construction Manager, General Contractor, Design Authority, and Flooring Contractor) with good, timely information that helps all involved plan ahead for the floor covering installation. As one of the last significant trades onsite, the flooring contractor needs certain conditions, that if not planned for in advance, will be next to impossible for the Construction Manager/General Contractor to provide without extra time and/or extra money: two things in short supply at the end of a build or renovation. Change is possible, but requires a few things to be understood and acted on in advance. There is a generic Canadian floor covering industry reference manual available for specification, which supports all construction parties, and when included in the Division 09 section of the construction documents, means correct flooring processes and supportive language is available to guide the floor installation and all the points listed below.

Contributed by Roy Schauffele The air barrier technology used in today’s construction and mandated by the International Energy Conservation Code (IECC) are firmly grounded in science. That database of knowledge continues to grow at an astounding rate. Research efforts by the Air Barrier Association of America (ABAA) will be presented at the ABAA Conference in 2019, and you will be astounded by how much research and testing that ABAA has been conducting to ensure better knowledge for all.

Currently, air barrier systems are being marketed with having passed only the air barrier part of the testing (ASTM E2357 - Standard Test Method for Determining Air Leakage of Air Barrier Assemblies) and pay little to no attention to the other architectural performance attributes, such as crack bridging, water resistance, adhesion to a substrate and fastener sealability, which when successfully passed, results in an ABAA Evaluated Assembly. So, what I’m asking you to consider is an upgrade of performance requirements for a better and stronger air barrier specification. Here are my suggestions for ensuring the best possible air barrier performance for your project:

Performance requirements for a proper air barrier specification are vital. The above are four of my suggestions as how you can elevate and upgrade your specs. Should you have any questions or comments, I appreciate you commenting below. Thank you for reading. Contributed by Dean Moilanen The finishing trades most often come into play at the end of the construction project. In many cases, the end result is decorative, ornamental, and breathes life into the vision of the finished project. The installation of ceramic tile and natural stone is a finishing trade which must deliver on an aesthetically pleasing expectation AND be a resilient, long lasting, wearing surface. Unfortunately, all too often, critical installation methods and standards are not followed, with the end result culminating in failure.

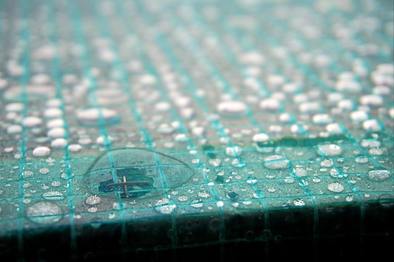

Ironically, this uptick in installation failure comes at a time when the combined forces of the tile and stone industry are proactively reaching out to offer training and certification for contractors and installers. The National Tile Contractors Association (NTCA), The Ceramic Tile Education Foundation (CTEF), and Advanced Certifications for Tile Installers (ACT) are just some of the organizations offering comprehensive education and training. The downturn in the construction industry, which occurred during the last recession, saw a vast outflow of qualified installers from the industry. The challenge still remains to locate and train individuals to address the demands of a rebounding trade. This challenge has played a role in some of the nagging failure issues that continue to occur. These failures are based more on a lack of installer knowledge and competence, then deliberate shoddy practices. Simply put, yes, you “really have to do that”, follow the ANSI or ASTM standard that is, if you want to steer clear of problems and failures. Listed below are just two of the concerns which need to be addressed in today’s ceramic tile and stone industry. If there is one overwhelming area of concern when it comes to the success or failure of a tile or stone installation, it would be the adequate bonding of the tile or stone to the substrate. ANSI A108.5-2.2.2 outlines the process of achieving the coverage needed to bond tile or stone to the wall or floor substrate. Summarized, the adhesive used to bond the tile or stone must be applied uniformly and evenly to the substrate; no “rainbow arches of adhesive”, no “five spotting” or daubs of adhesive placed in irregular fashion on the substrate, serving as “targets” for bonding of tile. Minimum coverage required (the amount of bonding agent affixed to the underside of the tile) can range from 80% in “dry” areas to 95% in wet areas. Wet area bonding has heightened concern, as any voids in the setting bed can serve to trap moisture and result in microbial growth (mold). The lack of adequate bond between the substrate and tile or stone finished surfaces is the culprit in all too many failures. Wet area waterproofing concerns continue to plague tile and stone installations as well. Of growing concern is the need for tile and stone shower detail to withstand vapor migration, as steam/vapor (resulting from shower usage) migrates to behind the tiled shower wall. The moisture damages the interior wall details and oftentimes finds a food source that contributes to mold. ASTM E96 Procedure E is a performance standard for waterproof membrane systems, which when called out in specifications ensures a “steam room” level of performance on the shower walls of these wet areas. Typically, the products meeting this standard are applied to the outer face of a suitable wall substrate in shower details, with the tile then bonded to the membrane. When assessing the viability of product to be used with regard to this ASTM standard, be sure to source independent third party testing for validating a product’s performance claims. There is now language and documentation available to architects and specification writers which calls for qualified labor, and is available from the National Tile Contractors Association. Implementation of this language would aid industry efforts to improve installation quality. |

AboutLet's Fix Construction is an avenue to offer creative solutions, separate myths from facts and erase misconceptions about the architecture, engineering and construction (AEC) industry. Check out Cherise's latest podcast

Get blog post notifications hereArchives

March 2022

Categories

All

|

RSS Feed

RSS Feed