|

Contributed by Eric D. Lussier Remember my post from February, entitled 'Project Compaction: Not Just for Soil'? Well, if you don't remember, didn't have the chance to read it, or would like a refresher, I'll give you a few minutes to jump over there and give it a read.

So, guess what? They're not quite ready yet. How close to not ready? Well, the picture above is from this past Friday, the seventh of June. On a project that was supposed to install in May. As a reminder, my company installs flooring. Flooring is a product that's supposed to go under that pallet of block, the forklift, those 55-gallon drums of something and the tons of miscellaneous equipment, dirt and debris that litters the gymnasium. If I've learning anything over my thirteen years of installations, its if you give someone a 5,000 square foot (or larger) space on a construction site, it will be used as a catch all for everything that doesn't fit somewhere else on a job. Kind of like that junk drawer that we all have in our house. Please forgive me for my sarcastic tone, but this isn't the first time I've seen site conditions like this, which was three mere days before we were due to start work. And, it certainly will not be the last time. I tried to be optimistic about their timeline request months ago. In early May, the basketball hoops were due to be installed "by Tuesday next". As of Friday, they're still not. So, along with my company, that's at least one other vendor who was given a commitment date that wasn't adhered to. I'm presuming there's at least a few others. So, despite our numerous written notices that "it is imperative that we are immediately notified if you will not be ready for the week of June 10th", our requests were ignored. Our last written communication has now gone unanswered for over two business days. And do you know how this will most likely shake out? Chances are we'll be given a very short notice that the site is "now ready" and we'll be expected to drop everything, juggle our schedule and refocus our attention on someone that was unable to be realistic about a project schedule for months. Buckle up and stay tuned for my next article focused around life as a finish trade.

1 Comment

Contributed by Eric D. Lussier I'm knee deep in a project right now that I'll call it what it really is: bailing the Owner out. Know what you get when you don't create bidding documents and rely solely on a low price? You get what you get. And if I say that phrase aloud in front of my 5 and 8-year-old, they add "and you don't pitch a fit".

Well, when one doesn't create an RFP, not to mention any sort of construction specification or drawing, how can one hold any level of expectation about their finished product? This Owner bought off a non-descriptive proposal and carried what matters most in the construction industry too much of the time: the lowest price. I don't have the time, the space, nor the want, to fully go down the road of the low-bid scenario. I will call it as I see it as a subcontractor: it's the short end of the stick. And yet it is still the "solution" for the most popular project delivery method in the construction industry today: design-bid-build. Let us Cliffs Notes design-bid-build within a tweet's 280-character limit: Owner has vision. Owner works with architect on design for vision. Architect develops schematics. Fine tunes. Vision formalized. Architect develops formal drawings & specifications for GC. Duration? Years? GC gets days to decipher vision. End result? Be cheapest. But that's simplifying things, you say. Sure, that may be. But in a nutshell, that's the process. One of the frustrating things about working with designers and developing specifications is becoming the basis of design, or an approved equal, only to be just breaking the sweat of the marathon race. Once you're named in a spec, you now must win the spec. And how do you ultimately win the spec? Match it and be the cheapest and ultimately, hope. Hope? Sure. Hope your price lands in the lap of the estimator in time. Hope they have time to read it. Hope they pick up what you're putting down. Hope they want to work with you. Hope you meet their qualifications to work together. Hope you can meet your estimate and make goal profit margin. Hope it all goes to plan. Hope you get paid in full in a timely fashion. Contributed by Eric D. Lussier With 2018 behind us, and with that another great year of articles, podcasts and many workshops across the nation (and even one in Canada), Let’s Fix Construction looks forward to 2019, as do many others. A new year starts with fresh energy, renewed spirit, a hopeful change of habits and a positive outlook.

With 2019 facing us and 2018 in the rearview mirror, Let’s Fix Construction is using this post for a Call to Arms. A challenge, if you will. Hopefully you can identify your role, or more than one, in this list. Don’t see a challenge that calls to you? Identify your own. Step out of your comfort zone and move yourself and the architecture, engineering and construction (AEC) industry forward. To Owners: Educate yourself before you proceed with your project, especially if it is your first one! Take the time to learn the roles of the major players in a building project. Vet your architect, construction manager, general contractor and any other major contractor or consultant that you are going to be contractually obligated to. You don’t have to be best friends, but it will go a long way if you know who you will be working with and get along with them. What makes them tick? What sets them off? What are their expectations? What are their expectations of you? And in the end, if you really want to educate yourself about a project, get a copy of the Construction Specifications Institute’s ‘Project Delivery Practice Guide’. It could just be the best $129 you’ve ever spent. AND save you a thousand-fold in the long run. To Architects: Projects are getting increasingly complex and the demands on you, your supporting staff and ultimately, your entire office are growing as well. The world we live in changes rapidly and with that the demands that are put on all the major players in a project. You’re being asked to do much more in much less time for the same amount of money. Practice saying no. Don’t be afraid to lose a client that expects more from you without understanding your point of view. Make sure you and your staff are compensated appropriately for your time. Track all costs and analyze your data. If you are able to reference a completed project that is similar in size and scope of a new project you are working on, you will be able to substantiate to the Owner why you have the requests, both financial and otherwise, that you do. Contributed by Cherise Lakeside This past October, Let's Fix Construction once again attended CONSTRUCT in Long Beach, California and as members of the Education Advisory Council, we found it to be one of the best yet. We are honored to partner and work with CONSTRUCT as the show holds much the same philosophy as we do here at Let’s Fix Construction: bringing all parties of the project team together to learn, discuss issues and grow as a TEAM. CONSTRUCT offers an environment where attendees can discuss issues in a way that we often cannot under the rules of communication in a construction Contract. There are few other conferences that have representative voices from the entire built environment in a room discussing our industry and needs - all with an equal seat. The best thing about CONSTRUCT is that it is not focused on any one discipline within the AEC Industry. Architects, Specifiers, Contractors, Engineers, Consultants, Subcontractors, Product Reps and Owners all have educational opportunities to learn and further your career. The social and collaborative environment of the show makes the education provided that much more valuable. CONSTRUCT is an annual event that offers the opportunity to share best practices, learn the latest in construction industry design and processes, project delivery, specifications, contract administration, building product manufacturer (BPM) education and much more. The education, events and show floor are all formatted in a way to serve any member of the building team. The education is enhanced by the ability to discuss and share experiences on topics that we deal with every day in this industry. CONSTRUCT is a great conference because of the diverse industry professionals that join us to share knowledge, solutions and real-world practices that can be used as soon as you return to your office or the job site. Speakers and instructors from all across the industry join us so we can all come to the table and learn from each other. CONSTRUCT WANTS YOU! The Call for Sessions for 2019 is out for submissions. CONSTRUCT is looking for industry leaders - in ALL disciplines - to consider submitting a proposal to speak or teach at CONSTRUCT. Now is your chance to share your knowledge and turn what you’ve learned into a unique presentation that will help improve the construction community. Consider submitting a proposal for CONSTRUCT 2019, which will be held October 9-11 at the Gaylord National Resort and Convention Center in National Harbor, Maryland (right across the bridge from Washington DC).

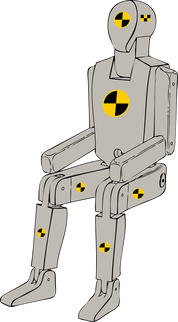

Contributed by Brian Stroik CRASH!

BANG! WOW! That was cool - the Crash Test Dummies have done their job again! The automotive industry found a way to ensure the safety performance for their deliverable for all manufacturers to owners (us), through testing and validation. Yet when we approach the subject of performance mockups within the building community, people seemed shocked at the suggestion. After all, it might cost something to make sure it gets done right the first time – heaven forbid! Now, consider this: buildings today utilize thousands of products, from hundreds of manufacturers, with thousands of different chemical compositions, being installed by a group with a known labor shortage, managed by groups with all different delivery methods. Try and figure out that matrix of possible outcomes. Add in the fact that very few architectural schools teach building physics to students for the understanding of heat, air, and moisture transfer, and it is no wonder insurance claims and litigation from moisture and water issues in construction is a billion-dollar industry annually. Let’s also ask the question: how many architectural firms have chemists or research and development labs or full-scale testing facilities? Very few. But as an industry, we are asking the architect to provide product choices in specifications and properly designed and detailed projects, with the full knowledge that no single person or firm could possibly know or understand all the technologies available for all six sides of the enclosure. So…how can the Owner be assured his building is being properly built? Use the building industry’s “Crash Test Dummy” – the performance mockup. The performance mockup is used to validate the design, product selection, and proper installation of materials, prior to the final installation on the building. Would you build a car in your backyard for your 16-year-old to drive on the expressway at 70 MPH? If you answered no, then why would you expect a unique combination of design, materials, and installers to be able to successfully provide an Owner with a leak-free building on their first try? Remember…. every building is UNIQUE. Even if you use the exact same design from project to project, you must add in the experience, or lack thereof, of the installers for each building. So, consider even if you design and select the exact same materials for two identical buildings, there is no feasible way they could be built in the exact same weather conditions, with the exact same labor force. It is impossible! The performance mockup can be built and tested in a myriad of configurations and at all levels of cost. The most important part is that they are tested - for water leakage, air leakage, thermal concerns and durability. Make sure people installing the mockup are also going to be working on the project. What good does it do the project if the knowledge gained by the mockup is not available for the actual construction of the project? Let’s do it right on the building the first time and aim to get the lawyers and litigation out of construction. This is the first in a four-part series on performance mockups. Stay tuned for more information. • Types of Mockups • Testing of Performance Mockups • Transferring knowledge from the Performance Mockup |

AboutLet's Fix Construction is an avenue to offer creative solutions, separate myths from facts and erase misconceptions about the architecture, engineering and construction (AEC) industry. Check out Cherise's latest podcast

Get blog post notifications hereArchives

March 2022

Categories

All

|

RSS Feed

RSS Feed