|

Contributed by Elias Saltz In my very first post on this site, the one titled, “Is Construction Broken?” I listed a few ways in which the profession of architecture is contributing to the ways in which construction is broken and needs to be fixed. I’m providing the link so readers can go back and refresh their memories on the whole collection but for the rest of this post I will be addressing my first observation, which read in part:

...architects see themselves as designing for themselves, or believe they’re working for the good of society, the environment, adopting “improving life” or other lofty goals that create real conflicts of interest that they don’t even recognize. One of the most prominent architecture school tropes is the studio crit, which goes something like this: After making incremental design revisions to their projects over the course of several weeks, students work several straight days and nights to create the beautiful models and drawings that would show off their work. They pin all the drawings up on the walls, stand bleary-eyed in front of all their fellow students and several professors who would serve as critics, and deliver an explanation for what they’ve done. Then they’d brace for the inevitable avalanche of negativity. A lot of the time, as I recall, the students would lace their explanations with the phrase, “I wanted to...” For example, they might use broad sweeping proclamations like, “I wanted to have a building that gave the impression of melding the sun and the sea.” Other times they didn’t have to be so lofty; then it would just be, “I wanted to put the classrooms next to the dining hall.” Well, guess what, architects and designers? Nobody cares what YOU want! Your desires are not relevant. You’re not hired to do what you want. You’re hired to help clients solve their problems and fill the needs they have for their facilities. These days when I watch home renovation shows on TV I often hear the shows’ designers tell the homeowners things like, “I want to create a sense of serenity in your master bath.” My response would be, “if that’s what you want, do it in your own house. You’re designing my house and you’re going to do what I want.” (as an aside, you never see episodes of those shows where the homeowners berate the result of the designers’ work no matter how stupid it looks) Clients give architects and designers authority to make myriad decisions on their behalf as to the planning, broad-picture and detailed design and material selections that go into their facilities because they lack the knowledge, skill and necessary time to make those decisions for themselves. They trust their architects to look out for their best interest, so when it comes to making decisions, architects, stop and ask yourself these questions:

7 Comments

Contributed by Marvin Kemp I use this line frequently with my children: be a part of the solution, not a part of the problem. The lesson is to solve problems, not point fingers. Think about this: when pointing your index finger at someone else, your other three fingers are pointing back at you. The other lesson of this message, though not overt, is to communicate to solve problems. Learn from your own shortcomings and work to correct them.

I attended a meeting this week with a client who we designed a building for, but they were unable to secure funding for construction once the documents were complete. The project sat for 2-1/2 years and now about 80% of the funding is available, so we are being asked to re-program the building to eliminate about 20% of the square footage. In the room at the meeting were 20 people, some of whom were involved in the original design and some of whom were not. There was much discussion of what should happen, but no offering up of solutions. There was a lot of "cloud talk" with little substance. I find this a lot with design and construction projects: people around the table that either do not understand the design and construction processes or understand a very limited swath of the process. How can we overcome this? Communicate, educate and collaborate. Nearly every problem in life can be solved by clearly, openly and honestly communicating. We all have sensibilities and needs that we bring to our work and to the projects we are involved in. Guard that those aren't turned into hidden agendas. Trust and communication break down when someone feels they have been wronged or not treated fairly. Be timely in how you communicate with your teammates and always be open and honest. More often than not, that honesty will be reciprocated. Since many clients will build one, maybe two buildings in their lifetimes, we should first and foremost educate our clients about the process, the pitfalls and the opportunities for success. There is a trust factor built in here: your clients will only be educated if they trust you and allow themselves to learn. Part of that trust is rooted in believability. Your explanation of process must sound believable and should not include phrases like "this is how it is done" or "because we have always done it that way." Trust is best built when all questions are answered and concerns are eased. We are stronger as a group than we are as individuals, so collaborating and utilizing everyone's skills and strengths to the fullest helps ensure success of the group. Collaboration is not easy; it is unlike any other relationship: it takes time to develop and it is built on trust. Honesty, confidentiality and accountability are the paving stones that collaboration is built on. Transparency is the glue that holds the collaboration together. I'm sure many of you try to practice these things in your dealings in our industry. Writing a blog post focused to members of our industry may be a bit like preaching to the choir: if you are out looking for help, you are probably already a part of the solution! Hopefully, this post gives you some vocabulary to use. Contributed by Elias Saltz Many of the listed contributors of the Let's Fix Construction team will be in Austin this week for the CSI Annual Convention and CONSTRUCT. Many words have already been written by the contributors to this blog (and others) about how getting together and having face to face dialog with our cohorts help us learn to better communicate with other stakeholders in the construction industry. This year will be no different in that regard. At CONSTRUCT, I plan to attend a variety of seminars covering the topics of building technology and specification effectiveness which will help me as an individual to improve what I do at work, and will allow me to share my own expertise as well. I can improve my own competence, make my company’s product better, and spread some wisdom at the same time.

What is a little different this year is that having become a contributor to Let’s Fix Construction, I will be thinking constantly about how what I am learning can be used more broadly by the readers of this site. I will think in terms of considering bigger picture “fixing construction” questions and not just focus on my own performance in my own little corner of the AEC world. Additionally, I plan a strategy of having as many side discussions as I can with professionals across the industry, listening to their opinions on the state of construction. I plan to build a dossier of those accumulated complaints, observations, ideas and solutions to round out my own contributions to Let’s Fix Construction. In order to push people into thinking beyond just their immediate concerns, I am coming up with a few talking points/questions to put to the people I encounter, and hopefully others will follow my lead and we can quickly accumulate some really good ideas to share more widely. The goal is to pose questions in order to gradually help people broaden their thinking. Rather than leaping to the biggest-picture questions first, I think it’s useful to ask them to focus first on their own business, which they naturally know best, and talk about how they relate to affiliated professionals. As we continue the discussion, I hope to provoke them to consider their own vantage of the industry as a whole and think about where they see the gaps and opportunities to fill those gaps. I suggest the rest of the LFC contributor team go with a similar goal of having in-depth talks with attendees and trade show vendors in order to come back energized to make use of our new platform. And of course, whether or not you contribute to LFC, I encourage everyone who attends CONSTRUCT to engage in as many in-depth conversations as they can in order to broaden the way we think about solving problems. Having so many of us in one place offers an opportunity too good to miss. Contributed by Jerry Fossey How do I specify Metal Composite Material (MCM) manufacturers vs. fabricators?

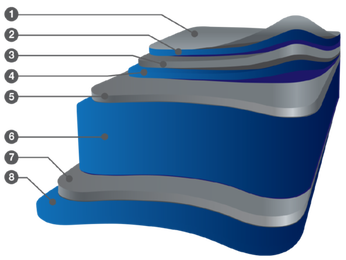

This is probably one of the most confused topics in the ACM/MCM industry, so I hope that this short post will help clarify the difference between the Manufacturer and Fabricator of Metal Composite Material (also known as Aluminum Composite Material or ACM). MCM consists of two skins of metal sandwiching a core material, which provides greater rigidity and superior flatness than sheet metal or plate. The MCM Manufacturer is the one that makes sheets of MCM, in a process where the skins and core are fused together in a continuous coil process. There are also some manufacturers that press skins to a core one sheet at a time, however this is generally known to be a lower quality bond, which is important when you consider the harsh conditions an exterior building envelope is required to withstand. The MCM Fabricator cuts, routs, folds and otherwise processes the MCM to fabricate panels to mount on the building. These fabricators can either have their own tested installation system using aluminum extrusions, or they can use a third party’s installation system. So which one should I specify? The MCM Manufacturer or the Fabricator? The answer is BOTH! There are many testing requirements, some of which apply to the Manufacturer and some to the Fabricator. Anything related to the MCM itself, such as fire rating and surface finish belong to the Manufacturer. Tests that require panel fabrication generally apply to the Fabricator, such as wind loads and water penetration. It is important then to clearly differentiate between the Manufacturer and the Fabricator in your specifications. I hope this helps build a greater understanding in the Composite Metal Wall Panel industry! |

AboutLet's Fix Construction is an avenue to offer creative solutions, separate myths from facts and erase misconceptions about the architecture, engineering and construction (AEC) industry. Check out Cherise's latest podcast

Get blog post notifications hereArchives

March 2022

Categories

All

|

RSS Feed

RSS Feed